Immersion heaters for non ferrous metals

From your need Atherm proposes you to calculate the solution, design it, produce it and participate to the commissioning and training when necessary.

Here is a non-exhaustive list of business segments where we have a recognized experience or entries :

- Foundries

- Furnaces manufacturers

- Aluminium producers (continuous casting)

Our head quarter near Grenoble with its comprehensive service (from R&D and quality up to shipment) trades worldwide.

Our subsidiaries in Qingdao China and Bangalore India serve locally.

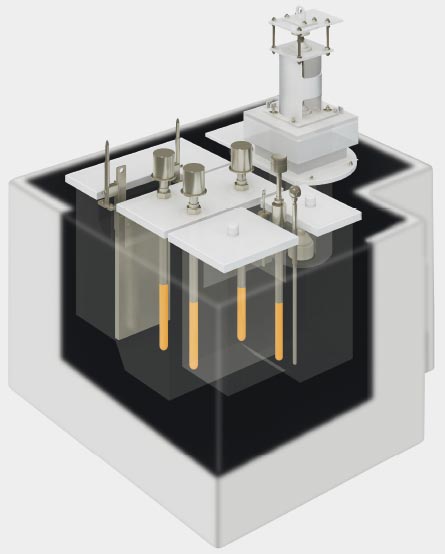

Immersion heaters in Aluminium Furnace

Energy savings:

up to 40%

Maintenance time:

from 3 hours to less than 1 hour

Liquid metal quality improvement :

no overheating, less dross

Temperature regulation:

accuracy +- 2°C

Environment friendly :

No CO2 emmissions

Products

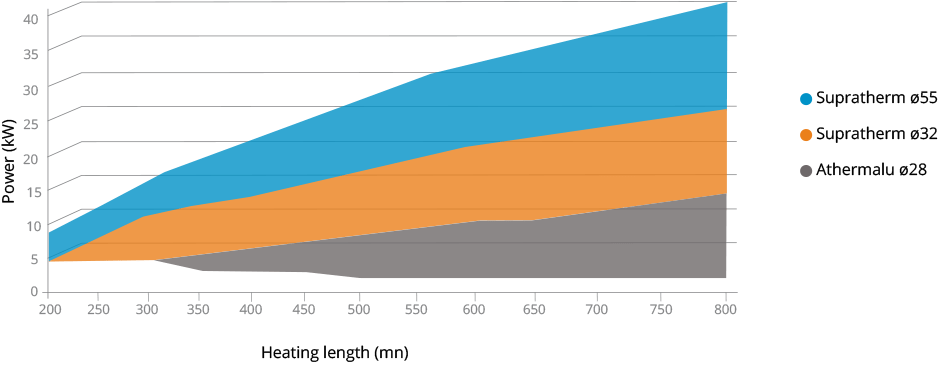

Power Range example

Process from design to customers installations

Design

A catalog product dimensioned and adapted to customers requests.

An experimented design office.

Made in France

600 immersion heaters per year

Diameters from 28 to 55mm

From 3 to 40kW

Technical assistance

Installation design phase assistance, commissioning and training assistance

Our customers

Aluminium producers

Foundries

Furnace manufacturers

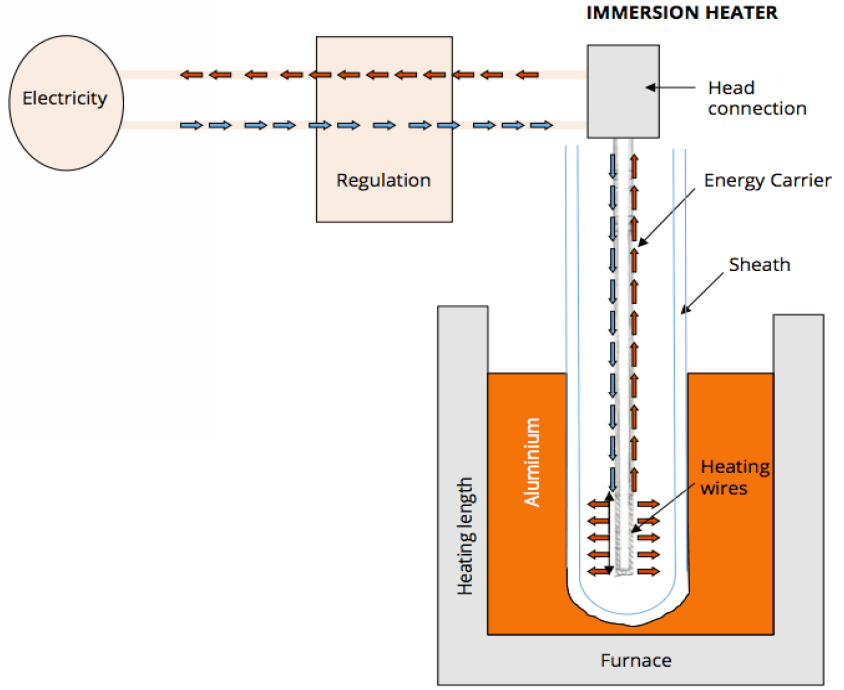

How it works

Heating

Heating in the heart of aluminum is the challenge, for that, you need to:

– Transport electricity

– Convert it to heat

– Transmit heat into the metal

– Have a reliable system

– Have a good life time

Immersion heaters, advantages

– High metallurgical quality and purity, less corundum (no over heating)

– Up to 40% energy saving with 100% yield (heat directly in the bath)

– Accurate regulation of bath temperature

– Temperature homogeneity (good for certain aluminium type)

– No CO2 emissions

– Usable for maintaining and reheating temperature

Energy savings:

up to 40%

Maintenance time:

from 3 hours to less than 1 hour

Liquid metal quality improvement :

no overheating, less dross

Temperature regulation:

accuracy +- 2°C

Environment friendly :

No CO2 emmissions