ACHIEVEMENTS

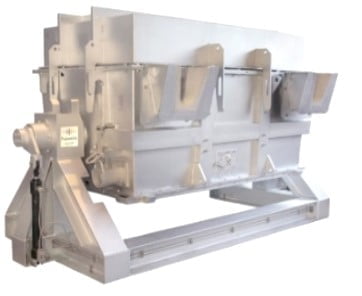

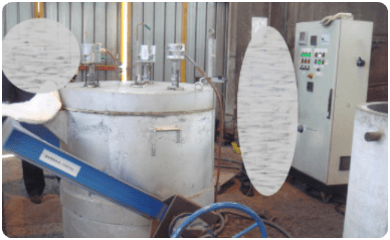

Holding furnace

2 chambers of 3.5T each to maintain in temperature

2×3 immersion heaters

Need in power: 240kW

– 3 immersion heaters dia 55, 40kW each, sheath 1320mm long

– Lifetime more than 2,5 years

– Piloted by a dedicated control cabinet

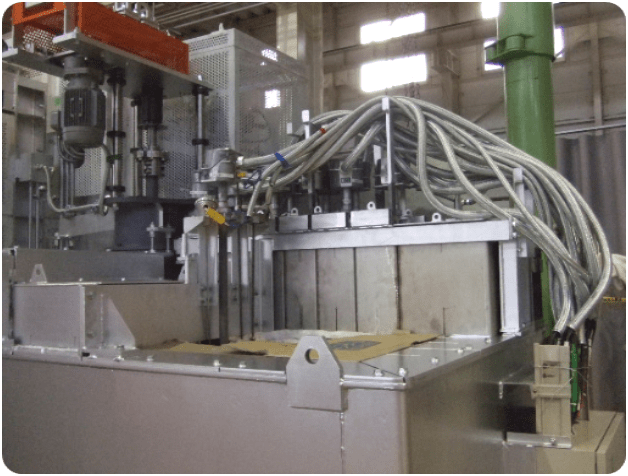

Melting furnace

Large industrial melting furnace

Molten aluminium and immersion heaters smelt solid aluminium

Temperature to hold at 750°C while smelting

– 13 immersion heaters dia 32, 13kW each

– Innovative industrial electric melting furnace

– Fully environmental friendly

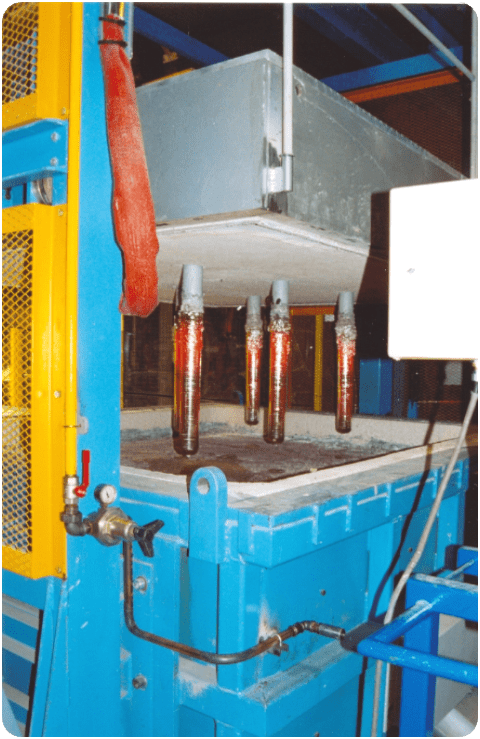

Crucible with dynamic reheating

– 400kg liquid aluminium

– 4 heaters dia 28mm, 15kW each

– Reheating from 750 to 800°C in 10 minutes

– A sensor detecting position of lid turning off heaters power

– The relevant piloting cabinet

– Quality of aluminium maintained

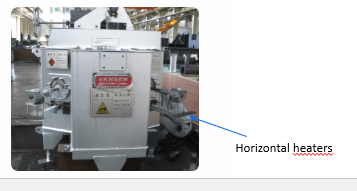

Filtration unit

Flow rate of aluminium at 4T/h

Need in maintaining and reheating

– 3 immersion heaters in horizontal position, offering 9kW each

– Physical and thermal dimensioning of heaters

– Proven tightness solution

– Relevant piloting cabinet

Transfer ladle

– A ladle of 1200kg of aluminium

– Temperature losses during transfer furnace/ladle and pouring ladle/mouldNecessity to reheat before pouring into a mould Keeping quality of aluminium

– A well insulated lid with holes for heaters- 3 heaters ø28, 15kW each

– Reheating from 700 to 760°C within 6 minutes

– Relevant piloting cabinet

Holding road transport ladle

– 6T

– Need in reheating 10°C/h up to 830°C

– 3 heaters ø32mm, 1400mm long, 15kW each

Replacement of vault resistances by heaters

– High dynamic

– Homogeneous temperature

– 40% less energy consumption

– 6 immersion heaters, 15kW each- Quality of aluminium unchanged, no corundum

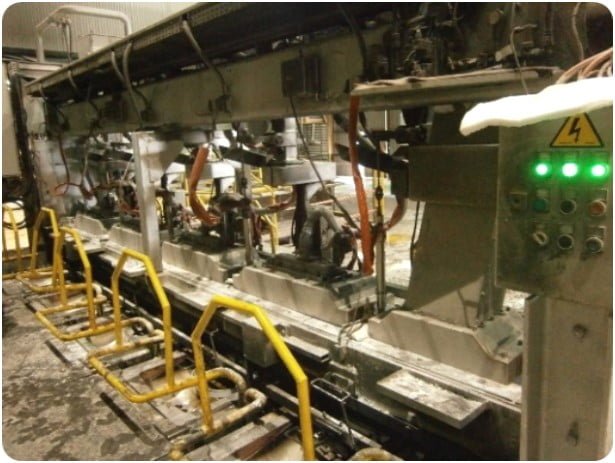

Retrofit of degassing unit

Replacement of inefficient and expensive graphite heating blocks

Rotors creating high temperature losses & a significant aluminium vortex

Possibility to have chloride and other additives

– Implementation of 1 heater per chamber, dia 55mm, standing additives

– Thermal, financial and qualitative efficiency of the solution

– Small heating length fitting bath level, 11kW each

– Good dynamic

Upholding during maintenance

28 vault furnaces 45kW each, with corundum

Aluminium temperature at 665°C

4 hrs to reheat before production restart when temperature falls down to 630°C

– 1 mobile station « Heat Pack »

– 1 heater 32 & Ø 55 12,5 kW each

– Gain 2 hours of maintenance on each 28 ovens, 2 times a month

Energy savings:

up to 40%

Maintenance time:

from 3 hours to less than 1 hour

Liquid metal quality improvement :

no overheating, less dross

Temperature regulation:

accuracy +- 2°C

Environment friendly :

No CO2 emmissions